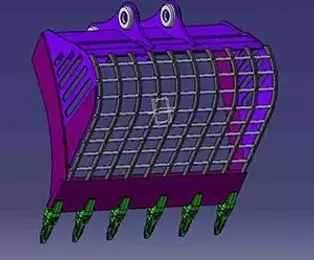

Screening Bucket

Screening buckets are the screening, crushing and mixing of soil, peat, shell and biomaterials, padding/trench filling, and screening/grinding of materials in industrial processes.

TYPES OF SCREEN BUCKETS

WHAT ELSE WE PROVIDE?

HIGH QUALITY

We offer you the highest quality with our continuously updated expert staff of 40 people.We try to achieve perfection by making different quality controls at every stage of the screen bucket production.

GUARANTEE

We provide one year warranty for our products and provide fast and cheap spare parts after the expiry of the period.

EASY SHIPPING

Get your product with our contracted shipping companies as soon as possible with minimum cost.

FUNCTIONS OF SCREEN BUCKETS

As the name suggests, screening buckets are a particular type of excavator and loader attachments, designed to “screen” materials. They are used for screening and separation of materials, both before and after a crushing phase. They feature a number of screening blades – designed in different configurations-, which allow different particle sizes of screened material, depending on the job’s requirements. Simply said, screening buckets are able to separate materials of a particular size or shape, that pass through them, from the rest of the matter.

Screen buckets are easy to use and multi-functional tools that can be used for separating materials such as top soil, construction waste, demolition, compost, etc. Typical screening applications include:

Less Maintenance

Easy And Quick To Use

20 - 50 Tonnes Machines

High Capacity

Cost Effective

-

Topsoil – to prepare a topsoil for projects like sport fields, landscaping and large gardens;

-

Padding and Back-filling – to screen dig materials for reuse padding pipeline and cables;

-

Composting – to create a high nutritional soil by mixing and aerating them;

-

Industrial Applications – to screen and separate raw materials;

-

Recycling – to separate fines from recyclable material;

-

Screening Peat – to screen stones, stumps and roots out, to process light material;

Light Weight

Ideal For Both Excavators And Wheel Loaders

Wide Range Of Products

Galen rotary screening bucket is ideal for demolition, excavation filling or pebble selection in waterways, screening and re-separation of organic wastes with sand, recovery of aggregates, selection of natural or waste materials for public maintenance, and rehabilitation of special green areas, stony land.

Rotary Screening bucket, equipped with a rotary basket in both directions, is easily interchangeable and with a network selection (min 10 × 10 – max 150 × 150), it is produced in 7 models for 1 to 40 ton excavators, also applies to mini loaders, backhoe and wheel loaders.In the case of unwanted impacts, the rotary screening bucket includes motor and hydraulic in the bucket, no drainage line is required, and the frame is in the shape of a truncated cone to increase the dredging screening surface.

ROTARY SCREENING BUCKETS

-

use for cylindrical screening, top soil screening, green waste recycling and separation of fine particles from rocks or aggregates

-

large capacity volume

-

epicyclic gear motor rotary screening drum drive

-

Robust, reliable frames built to withstand even the heaviest workloads

-

Primary screening of scrap material, demolition material, excavation filling material and material resulting from the reclamation of rocky soil

-

Gravel selection in waterways

-

Beach cleaning

Nothing for material selection cleaning and screening Galen rotary screening bucket perform better.With its high capacity open fronted drum design and simple hammer line feeding operation, Rotary Screening Bucket offers the highest level in material scanning and sorting.

Galen Rotary Screening bucket is equipped with interchangeable mesh system and interchangeable sections around the inner circumference of a drum in the conical back area of the drum. A bolt in the machine mounting bracket ensures maximum use between machines of various sizes. Seven models are available to suit mini excavators from 3 tons to 40 tons excavators.